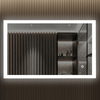

Construction sites are bustling arenas of activity. Amidst the hustle, ensuring the safety and productivity of the crew is paramount. Proper lighting is a linchpin in achieving this. Traditional halogen or incandescent bulbs might have been the norm a decade ago, but today, the construction industry in the USA is moving towards more energy-efficient and durable solutions: LED work lights. More specifically, linkable LED work lights encased in protective cages offering 360 degrees of illumination.

But how can these lights be best used for maximum safety and effectiveness? Let’s delve into the three essential steps for a robust construction lighting plan.

1. Understanding the Need for LED Work Lights with Cages

The strength and durability of LED lights are unmatched. They offer:

- Longevity: On average, LEDs last 25 times longer than their incandescent counterparts.

- Energy Efficiency: LEDs use 75% less energy, leading to substantial cost savings.

- Bright & Clear Illumination: LEDs produce a crisp, white light, enhancing visibility.

Now, imagine this illumination spread in every direction. That's the beauty of 360 degrees lighting, which provides comprehensive coverage.

The cage? It's imperative for protection. Construction sites are accident-prone. A dropped tool or an unexpected swing can break a light. Cages act as a protective shield, ensuring the lights stay intact and the site remains illuminated.

2. Embracing the 360 Degrees Lighting Advantage

360 degrees LED work lights transform site illumination in ways unparalleled. Here's how:

- Complete Coverage: With light emitting uniformly in every direction, there's no corner left in shadow.

- Reduced Number of Lights: Thanks to their comprehensive spread, fewer lights can cover more area, leading to savings.

- Safety Boost: With no blind spots, the safety quotient of your site skyrockets.

3. Exploring the Benefits of Linkable Lights

Linkable LED work lights revolutionize site illumination. Here’s why they are becoming a must-have for US constructors:

- Flexibility: Customize illumination by linking multiple lights as per site needs.

- Ease of Installation: Reduce wiring hassles. Just link, and light!

- Uniform Lighting: Paired with 360-degree illumination, ensure there's an even spread of light across the site.

- Scalability: As the construction progresses, add more lights to the chain without fuss.

4. Implementing the Lights for Maximum Safety

Here’s a quick guide to setting up your linkable 360-degree LED work lights with cages:

- Analyze the Site: Identify vital areas that need bright illumination, like scaffolding or entry points.

- Position Intelligently: With 360-degree lights, ensure they're placed at strategic intervals for maximum coverage without redundancy.

- Regular Maintenance: Inspect the lights, their connections, and cages. Clean periodically to maintain optimal output.

Conclusion

The construction landscape in the USA is advancing with a focus on safety and efficiency. LED work lights, particularly those that are linkable, caged, and offer 360-degree lighting, are leading this change. These are not just trends; they are the foundation of modern, safe, and efficient construction sites.