Lighting is a critical component of chemical plants, where accuracy, safety, and efficiency are not compromise-able factors. The demands of the environment are so unique that they require lighting solutions that are durable, energy-efficient, and strict in terms of safety regulation compliance. In this blog, we will explore the best lighting options for chemical plants, their benefits, and factors to consider when choosing the right fixtures.

Why Lighting is Important in Chemical Plants

Chemical plants are complex units having operations running 24*7. Proper lighting in the following ways:

- Enhance Safety: Proper illumination is bound to reduce chances of accidents like slips or leakage of chemicals.

- Increase Productivity: The visibility in turn enhances the work quality at the workplace even in hazardous conditions or low light.

- Meet Regulatory Requirements: Industry-specific standard of lighting ensures adherence to the safety norms.

- Conserve Energy: Proper lights minimize energy consumption. Ultimately, this reduces operational expenses.

Challenges in Chemical Plant Lighting

Lighting in chemical plants should consider specific challenges, such as:

- Hazardous Locations: The presence of flammable gases, vapors, or dust requires Explosion Proof Lighting.

- Corrosive Environments: Chemicals may corrode standard fixtures, requiring strong materials such as stainless steel or aluminum.

- High Temperatures: The lighting solution must withstand the intense heat produced by chemical processes.

- Continuous Operations: Fixtures should be long-lasting and low-maintenance to prevent frequent replacement.

Best Lighting Solutions for Chemical Plants

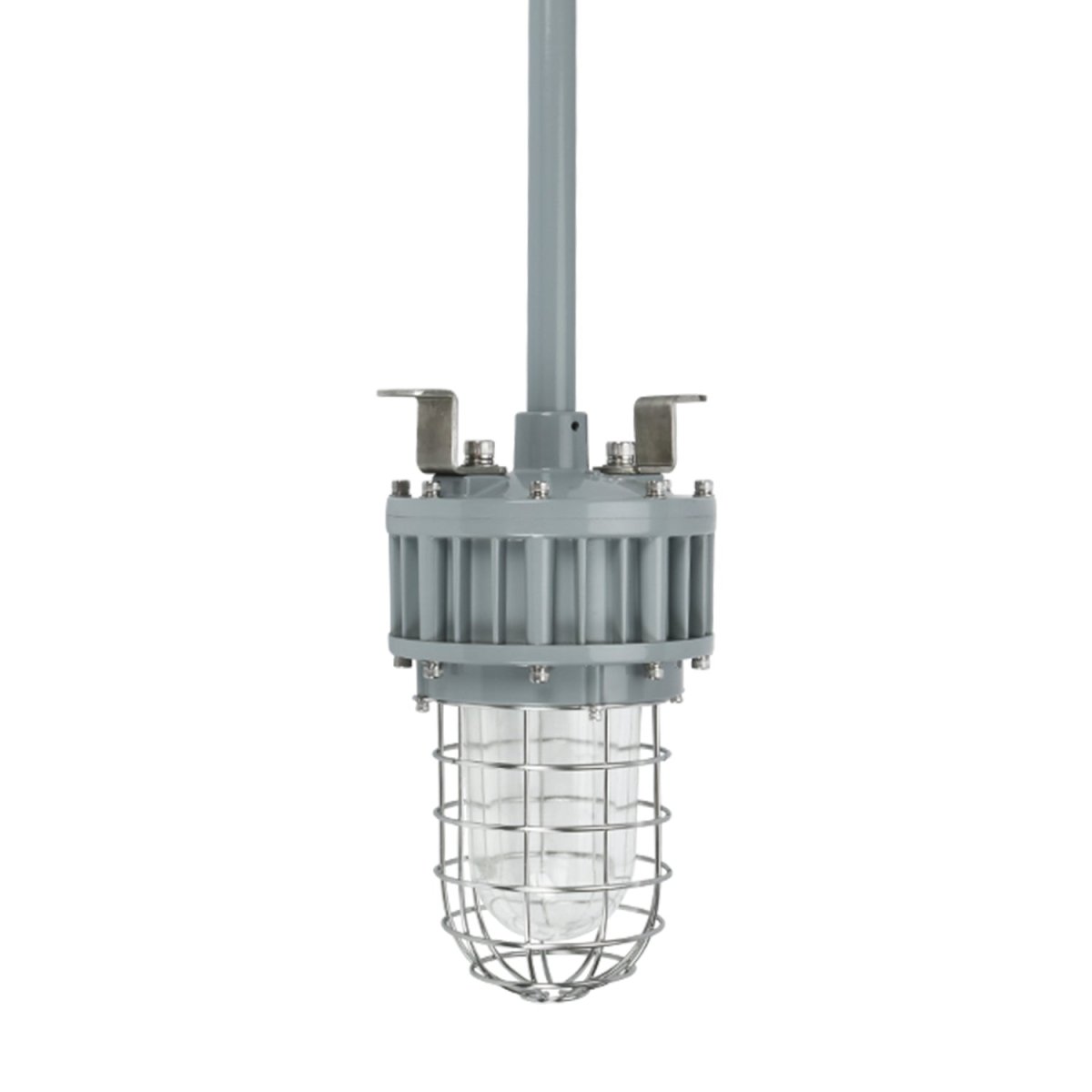

- Explosion-Proof LED Lights

These lamps ensure safe performance in potentially hazardous environments to avoid the ignition of flammable materials. They offer benefits such as:

- High ruggedness

- Extra energy efficiency

- Conformity to safety standards like ATEX or IECEx

- High Bay LED Lights

Excellent solution for wide spaces such as storerooms or manufacturing warehouses. Features:

- Symmetrical light dispersion

- Very long life: 50,000 hours and beyond

- Energy-saving is greatly optimized

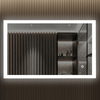

- Rust Resistant Fittings

Ideal for environments exposed to harsh chemicals or moisture. These lights are built with anti-corrosive materials and protective coatings to ensure longevity.

- Emergency Lighting Systems

Crucial for maintaining visibility during power outages or emergencies, ensuring worker safety and smooth evacuation.

Key Factors to Consider

When selecting lighting for chemical plants, prioritize the following:

- Safety Standards: Ensure the fixtures meet industry-specific certifications.

- Energy Efficiency: Opt for LED technology to reduce energy costs and environmental impact.

- Durability: Use lights with higher IP ratings to resist dust, water, and chemicals.

- Customization: Implement lighting solutions according to zones, like control rooms, production areas, and outdoors.

Advantages of Replacing Traditional Lighting with LED Lighting

LED lighting has a multitude of advantages:

- Energy efficiency: LEDs use 80% less energy than old lighting systems.

- Lower replacement cost: The longer lifespan eliminates frequent replacement.

- Light intensity: LED lighting produces light with greater intensity, not to mention flicker free, perfect for precise activities.

- Eco-Friendly: LEDs contain no hazardous materials such as mercury and are recyclable.

Conclusion-

Lighting in chemical plants is more than a necessity; it's a cornerstone of safety, efficiency, and compliance. Chemical plants can optimize operations, enhance worker safety, and reduce energy consumption by investing in advanced LED lighting solutions tailored to their unique challenges. Look for a chemical plant's reliable lighting solution. Find high-quality, energy-efficient, and compliant LED lighting solutions at LEDMyplace for industrial demands.