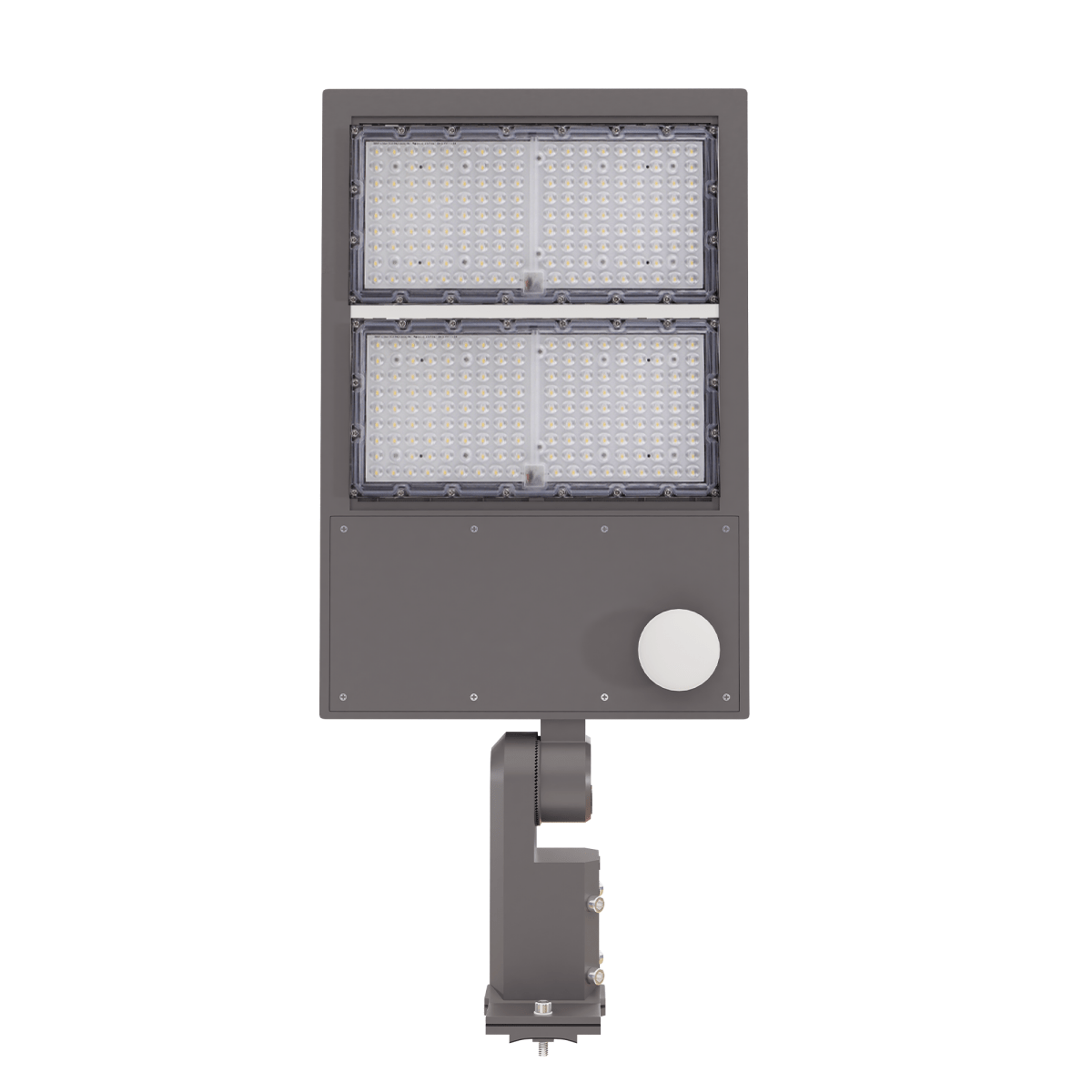

Switching from any traditional lighting source (e.g., HID or halogen lamps) to LED lights for your parking lot will be unquestionably more beneficial. Because in the long term, LED parking lot lights will deliver higher efficiency, more savings, and have a longer life span.

And if you want to maximize your savings further and enhance performance, make sure to add controls to your LED parking lot lights.

LED lights can be regulated and controlled in a number of ways. These solutions can be installed as a stand-alone system or combined to provide even greater efficiency.

The following are five popular ways to control LED parking lot lights:

Time clocks are divided into two categories. First, there is the analog version, which is relatively easy to use. It features a dial with times listed on it, and the user sets the "on arrow" and the "off arrow" to the times they want the parking lot lights to turn on and off. This is a low-cost alternative, but it frequently necessitates user modifications as sunset and sunrise times vary around the year.

The second is the digital time clock version, which is a much more preferable solution for parking lot lighting. They are a little more expensive up front, but they can account for shifting dawn and sunset times, removing the need for the end-user to make adjustments after a one-time installation.

Photocells can be used to control LED parking lot lights by installing a photocell:

- individually on each light fixture, or

- as part of a contractor that can control lights through the bank of lights.

The use of photocells eliminates the need for guesswork when turning on or off parking lot lights.

Photocells function on the principle that if it's dark outside, your parking lot lights turn on, and if it's bright outside, they stay off. Photocells also benefit from turning on the parking lot lights during the day if the situation necessitates it. For example, a storm or other natural occurrence may require the LED pole light fixture to be switched on.

Installing a photocell on every fixture while retrofitting an existing lot is quicker for the installation procedure but may present more complications and maintenance down the line. The most efficient way to use a photocell is to operate a contactor with it.

There are many sensors available on the market, each with its own set of functions and options. The most simple ones will switch a light fixture on or off for a specific period of time. The more sophisticated sensors can reduce the light and gradually restore it to full brightness, or even use a built-in daylight harvester to change the brightness of the light until the space is lighted to a predetermined level.

As a stand-alone application, each occupancy sensor is mounted on each fixture and will turn on/off or dim light independently as occupants trip one light after another.

Incorporating an occupancy sensor into a wireless control system is a more superior approach. This reduces the number of sensors required, allowing banks of lights to be controlled by a single sensor and also allowing the end-user to make simple adjustments to the sensor's programming.

Wireless parking lot lighting controls have the highest initial cost, but they provide customers with the most options and flexibility. Their initial cost is frequently covered by increased energy savings, resulting in thousands of dollars saved in the long run.

Wireless controls frequently necessitate additional hardware installation inside the driver, and they all communicate with a single central control unit. These systems can be as simple as turning on or off lights and dimming them, as complex as gathering a wide range of data and delivering alerts to end-users, or even as complex as triggering if-then statements coded into the controller.

Changes to the system can be made from a single location, or if the system is connected to the internet, changes can be performed from anywhere the end-user has access to the internet.

“DALI” is a programming capability included in some drivers. Its function is to eliminate the need to connect any additional hardware to the fixture. It allows the driver to be pre-programmed with an on/off or dimming schedule.

The disadvantage of this lighting control method is that each driver must be programmed separately, which adds to labor costs in instances where fixtures have two drivers. Another disadvantage is that once the driver has been programmed, any changes must be made by physically reconnecting the programmer to the driver.