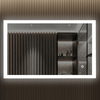

LED warehouse lighting is preferred for lighting warehouses as they have efficient features that help in improving productivity. Simultaneously, these lights are more capable than just illuminating the premises. You can even create a safe ad sound working environment if you prefer the LED warehouse lighting. Moving forward, you will learn how LED warehouse lighting helps improve your warehouses.

Improved industrial warehouse lighting does not have risky installation

It is not necessary that accidents take place in this critical working environment due to hefty machinery. However, sometimes, a poor fixture installation can cause some serious troubles too. So, keeping in mind that scenario, the LED warehouse light fixtures are designed so that they don’t contain a problematic installation process.

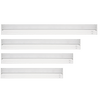

High bay lights like LED UFO lights and linear high bay lights are highly preferred in warehouses. This is because they don’t just offer great illumination but installing them is not chaotic at all. Therefore, this easy installation promotes a non-risky environment.

If you are worried that a simple installation might lead to wobbling or poorly installed fixtures, then don’t because these LED high bay lights are firmly installed, and they will not be a cause of workspace accidents.

LED warehouse lighting has a better CRI

CRI refers to the color rendering index that helps the LED lights show several objects' colors. The higher the CRI rate an LED warehouse light will possess, the more you will be able to identify objects in their actual colors.

LED warehouse lighting comes with >80 CRI, which is considered to be one of the most suitable rates. This is because it allows the light to display objects in their true shades.

In a relentless working environment like a warehouse, being constantly able to detect the true colors of objects is a must, as you cannot afford to be wrong. Similarly, a little misunderstanding or error in judgment can cause serious trouble to the organization. Thus, opting for LED lights like high bay lights UFO and linear high bays in warehouses can be really helpful as they have better CRI that helps in detecting colors as the natural light will do.

An LED warehouse doesn’t cause trouble to the environment

You cannot deny the fact that conventional lights are considered harmful to the environment because they contain harmful contents and emits toxic gases to the environment. This can really be problematic for future references.

However, going fully LED warehouse can reduce this issue as the LED lights don’t contain harmful toxins. Also, it emits comparatively less heat that does not imbalance the atmospheric temperature. Thus, this is a great way to create a safe yet improved warehouse environment.

Better lighting creates a safer working environment

As explained above, LED warehouse light fixtures have high CRI that helps in improving visibility. Opting for LED for lighting warehouse can turn out to be fruitful because it results in creating a safe and sound environment for the workers.

With better lights, the workers can see clearly and focus on their tasks without any chaos. Also, this eliminates the risks of accidents by letting people avoid tripping, slipping, or bumping into things.

Moreover, LED warehouse lighting comes with several safety standards ensuring the credibility of the fixtures against unsecured scenarios to avoid hazardous outcomes like fire, power failure, short circuits, etcetera.

Upgraded LED warehouse lighting to promote longevity

It can be noticed that industrial warehouse lighting fixtures are continuously upgrading their features to come out as a better alternative. Nowadays, LED warehouse lights are available with a motion sensor, dimmable feature, tunable CTT, timers, and several other smart features that promote the fixture's longevity and versatility.

Some warehouse lighting fixtures like the high bay light, low bay lights, troffer lights, receded downlights, etcetera are comprised of these upgraded smart features.

Most importantly, high bay lights UFO and linear high bays are available with motion sensors that automatically turn the light off when no motion is detected for 35-45 seconds. Therefore, it is helping in reducing the power consumption bills by reducing unnecessary light usage.

Conclusion:

In the end, LED warehouse lighting is undoubtedly a better option to enhance the security of the warehouse premises and the security of the workers. Furthermore, the lights are ideal for creating a suitable working environment for the employees and benefitting the environment.

Adding to that, lighting warehouse with LED lights can be cost-effective, low-maintenance, energy-efficient, and long-lasting. So, opt for the LED warehouse concept to avail these benefits along with improved security in your workspace.