An LED tube is not just a single tube. An LED tube is so many LED chips working together. If you open an LED tube, you will find rows of LED tubes with a lot of LED chips on each row. On either end, you will find aluminum covering, which also connects the power supply to the LED strips. These LED caps also serve as the heat sink for the fixtures. The operating temperature of these LEDs is lower compared to the HIDs and HPSs. The overall illumination is the sum of many individual electroluminescent transitions. All of these transitions happen at lower energy levels, so lower power inputs are enough. Lower power consumption, hence lower heating temperatures. This is unlike halides, which take 30 minutes to heat up and light.

History Of LED Tube Lights

LEDs have no exact birthdays. In the early 2000s, the development of better versions of LED tubes took place. In these years, these developments set the base for current LED tube lights.

In the last month of 2014, replacement for T8 fluorescent lights came out. This is a standard model(EN2776), adopted universally as a replacement by all the brands.

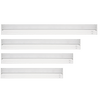

Primarily, LED tubes come in three different lengths, those are:

2 Foot LED Tubes: With 2 feets size, the LED tubes come in 8 watt and replace fluorescent tubes of 50-watt capacity. These ligts have small size, hence are perfect for lighting small sized rooms.

4 Foot LED Tubes: LED tube light fixture t8 4ft are used in medium-sized rooms and halls. They come in 3 different wattages-

18 watts replace 40 watts fluorescent fixture, 20 watt replaces 50 watts of fluorescent light, and 22 watts replaces 60 watts.

This size of the LED tube is appropriate for medium-sized rooms where high lighting output is needed, but the availability of space is restricted. LED tubes in this size come in three different wattages.

8 Foot LED tubes: These are used to light up large halls or big rooms with 40 watt LED replacing 100-watt fluorescent, and 48 watt LED replacing 120-watt fluorescent.

1st generation Retro-Fit LED tubes-

The first market fit version of this light came between 2005 and 2010, with no focus on quality and safety. Some European authorities banned them for some safety risks. This resulted in a sales ban.

2nd generation of Retro-Fit LED tubes

The second generation of LEDs had no drawbacks to the previous series. There was no risk of electric shock while installing. It used starter wire to conduct electricity to another end.

3rd generation of Retro-Fit LED tubes

LED lights emit a directional beam, and it posed a problem. Due to this nature of light, overall performance was a function of optics used and placement of luminaire. In the third generation of LED tubes, the focus was only to enable these lights to work independently of those requirements by increasing its output lumens. As a result, in terms of lumen output, these lights outperformed the fluorescents.

4th generation of Retro-Fit LED tubes

The 4th generation of LED tubes were the ones that eliminated the flickering issue of fluorescent lights. Many scientific researches in the past showed that flickering causes anxiety and cause a decline in productivity. This was the time when flicker-free lights came in to being.

Fluorescent lights were full of flickers, and was harsh to eyes. LEDs were powerful replacement, which offered benefits beyond expectations.

Beam Angles Considerations-

Before we dive into the comparison of the directional properties of these lights, let us go through the following terminology.

Beam Angles- A beam angle is the measure of the distribution of light. It is measured in angles. There are four angles-

- 8° – 15° = Spot

- 20° – 35° = Narrow Flood

- 35° – 55° = Flood

- 60° and greater = Wide Flood

Old lighting could not spread lighting on their own. They need an integration of parabolic reflectors (PAR), to direct these light beams. Incandescent or Fluorescent lights are not directional lights without such integration.

LEDs are not inherently directional, though, but the closest thing to it. The most efficient way to direct light beam was to enclose the light in an epoxy capsule, which throws the light forward. It is not that LED lights are omnidirectional in general. There are many illumination grade LEDs that have a broad distribution of light. Much of the LEDs are a great replacement to HIDs and fluorescent lights. LEd lights replaced the old lights as they offered lights with a variety of angles.

LEDs, in general, illuminate the lights in 230-degree angle, and Omni-directional LEDs project light between 270 to 300-degree angle.

LEDs project light to around a 230-degree angle; the Omni Directional LEDs give out light in a 270 to 300-degree angle. This pattern of view makes them well suited for anywhere that non-directional light is needed.

Some LEDs tube have opaque layers over them, which absorb the light falling on the layer and spreads the rest. Based on the coating, there are two types of LED lights.

Clear:

Clear LED tube is 40% brighter than the frosted LED tube because they have no coating over the tube. These are sometimes uncomfortable to look at because there is no coating over the light. These lights are used in tunnels or places where high lumen output is required.

Frosted:

Frosted LED tubes have a coating on them, which stops 40% of light out of the led tube light fixture. Frosted LED tubes are used in the offices, study rooms, and resting places.

Other Considerations-

High CRI- LED tube lights like other LED lights, offer excellent CRI. In the case of LED tube lights, it is more than 90. LED tube lighting offer CRIs that incandescent bulbs could ever achieve, in one-fourth of the power consumption.

Low Power Consumption-

In the opening paragraph, you might have read that LEDs lights are energy efficient. They are energy-efficient to the extent that they recover their cost within 2-3 years.

Long-Lasting- LED tube lights have an overall lifetime of 50,000 hours, roughly ten times more than the old lights.

1 comment

Schöner Artikel. Vielen Daank für die guten Infos.