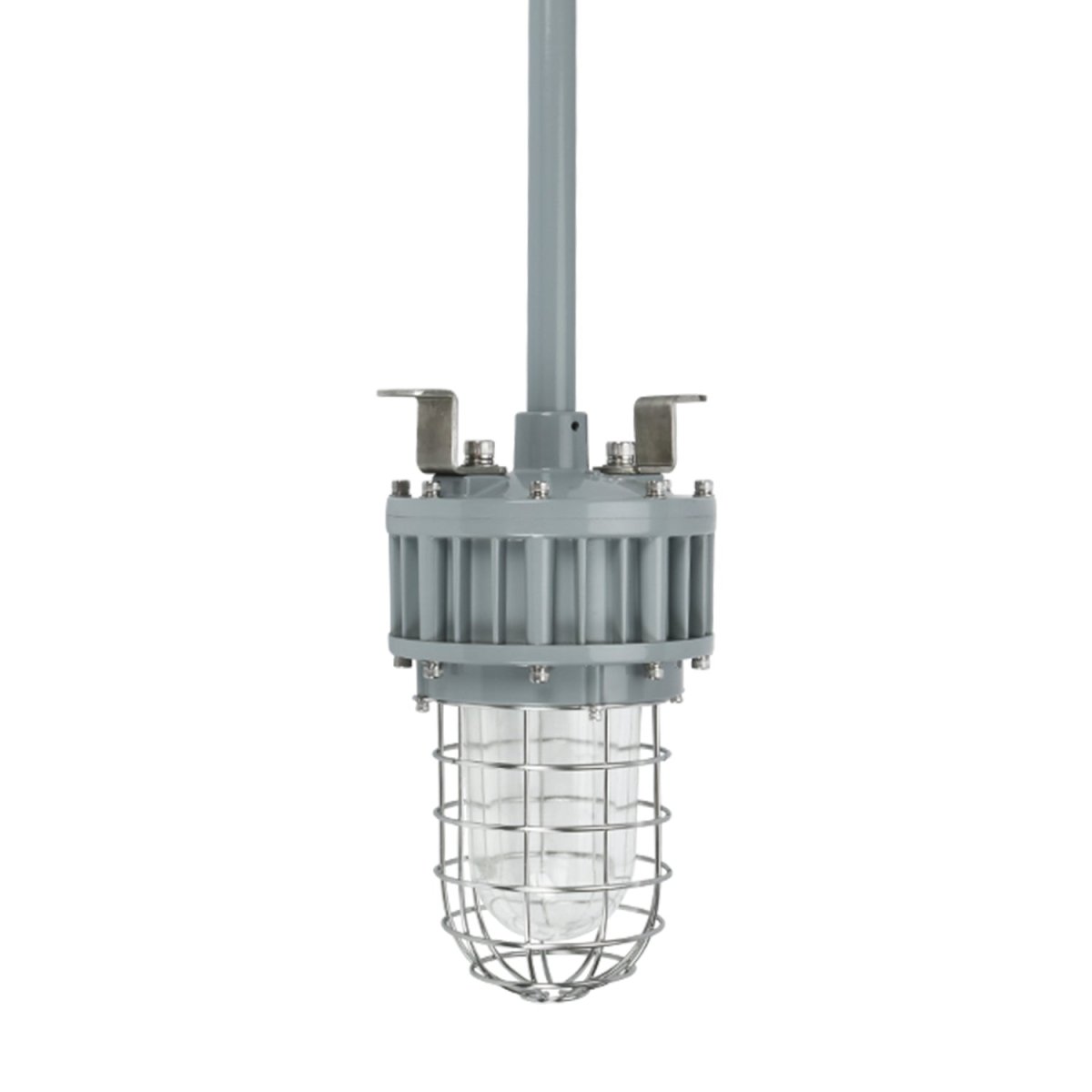

Such installations are used both for lightening areas and ensuring security; they are found in an industrial and hazardous setting. This is explosion-proof lighting-the specific type of lighting supposed to avert the ignition of combustible gases, vapors, and dusts. In search of such LED Explosion Proof Lighting, it is always important first to know what the specific code and regulation on its application stipulates so as to fulfill all requirements of safety features.

Understanding Explosion-Proof Lighting

Explosion-proof lighting is designed to trap sparks, heat, and any possible sources of ignition inside the fixture. These lights are a necessity in oil and gas, chemical manufacturing, mining, and many other industries. But what codes govern their design and application?

The Code for Explosion-Proof Lighting

Explosion-proof lighting in the United States must adhere to certain standards and codes:

- National Electric Code (NEC)

The NEC gives general guidelines for electrical installations in hazardous locations. Specifically:

Articles 500-506 classification of hazardous locations (Class I, II, III).

Fixtures must meet the class, division, or zone where they are installed.

- UL Standards

Underwriters Laboratories (UL) has developed standards for explosion-proof equipment, including lighting:

UL 844 certifies lighting fixtures for hazardous locations.

These standards check the performance of lights that do not cause ignition of flammable materials.

- OSHA Standards

OSHA regulations require explosion-proof lighting for workplaces where fire or explosion may occur.

- IEC and ATEX Standards

For international markets, additional standards are provided by the IEC and ATEX Directive that are used in Europe for explosion-proof lighting.

- NEMA Ratings

Explosion-proof lights must also comply with NEMA enclosure ratings to guarantee they can survive environmental exposures such as dust, moisture, and heat.

Why Opt for LED Explosion Proof Lighting?

LED Explosion Proof Lighting has many advantages over conventional lighting technologies like incandescent or fluorescent lights:

Energy Saver: LEDs consume less energy and that’s how they are considered as energy efficient.

Long Time Span: Because these lights have a longer life they do not require frequent replacement.

Durable: These fixtures resist the shock and vibration so are considered as perfect for industrial applications.

Eco-Friendly: LEDs are free from the harmful substances such as mercury and emit less heat so they are also Eco-Friendly.

Compliance: Modern LED solutions meet or exceed industry standards in terms of safety and reliability.

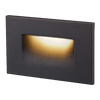

Where to Use LED Explosion Proof Lighting?

- Oil Refineries

- Chemical Processing Plants

- Grain Storage Facilities

- Mining Operations

- Paint Shops

- Power Plants

They have been categorized as having the presence of ignitable gases, vapors, or dust. Safety and compliance for the correct light fixture used in the categorization

Conclusion-

Including LED Explosion Proof Lighting in your facility ensures not only safety codes compliance but also efficient and reliable performance in hazardous environments. Always seek a professional's opinion in selecting the right lighting solution that suits your specific needs.

LEDMyplace offers you a great range of certified explosion-proof lighting solutions that help you meet industry standards and provide safe conditions for your working environment. Browse through our collection to find the perfect fixture for your application!