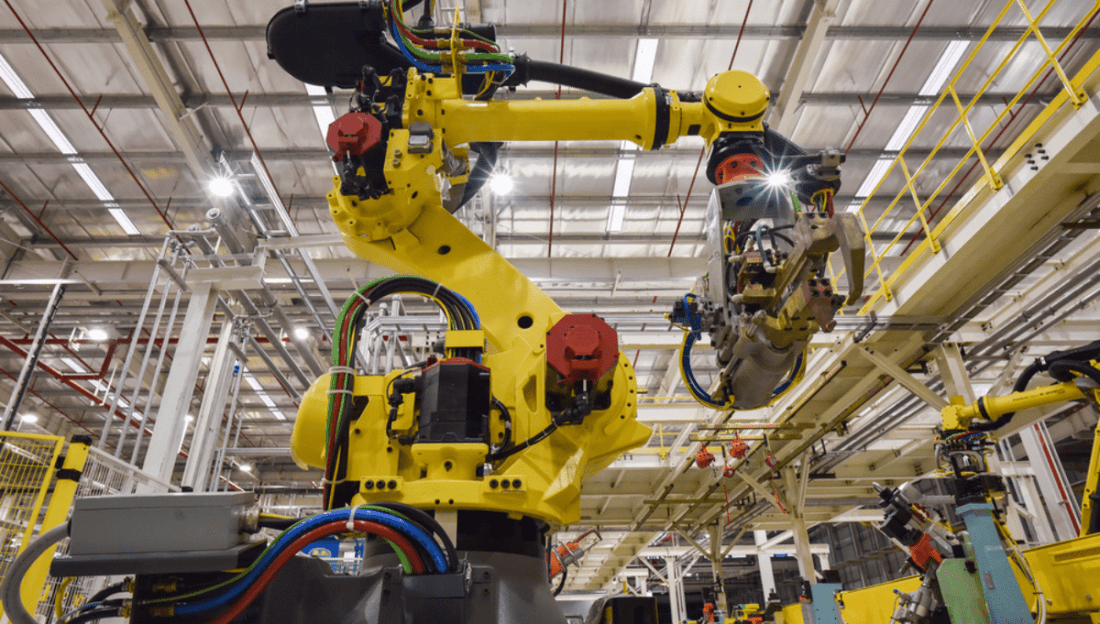

Proper lighting is a vital aspect of factory places and they directly impact productivity, safety and energy sustainability. Choosing lights with lighting standards ensures your workspace is bright and well lit for workers to do their task without any interruptions, this blog will help you explore the key aspects of factory lights and also how LED factory lighting can be an ideal solution of the performance.

Significance of Lighting Standards in Factory Premises

Factory settings range from assembly, inspection work, and heavy machinery work. Inadequate illumination leads to:

- More occurrences of accidents at the place

- Low productivity

- Eye irritation and fatigue among workers

- Increased chances of low-quality product due to mistakes

Standards of lighting ensure a light level that is uniform, thus providing a safe workplace with efficient working conditions.

Important Lighting Standards for Factory Settings

Several organizations have laid down standards for industrial lighting. The most commonly mentioned standards are:

- Illuminance Levels (Lux Requirements)

General work spaces: 150-300 lux

Detailed tasks like assembly: 500-1,000 lux

Precision work like quality checking: 1,500-2,000 lux

- Uniformity Ratio

Lighting needs to be uniform so as not to create shadows or dark spots. The ratio of uniformity should range between 0.6 or more for most industrial applications.

- Color Rendering Index (CRI)

A high CRI (80+) is needed when the task involves the need for color accuracy, for example, product inspection.

- Glare Control

Too much glare hurts and distracts. Factories should not lack anti-glare measures for visual comfort.

- Efficiency

Standards also motivate energy-efficient lighting systems so that the cost of running the operations is cut and so is the impact on the environment.

Why Choose LED Factory Lighting?

The introduction of LEDs has made a tremendous impact upon industrial lighting, bringing practical and economic solutions. The chief benefits of LED factory illumination are listed below.

- Energy Efficiency

LED illumination consumes 75% of the power compared to normal lighting, saving considerable electricity usage costs.

- Prolonged Life Duration

The LED illuminative system can work up to 50,000 hours with low maintenance needs for a factory setting.

- High Brightness and Uniformity

LEDs provide bright, consistent light, meeting the lux requirements for various factory tasks.

- Enhanced Safety Features

LED lights do not produce much heat, hence there is a lesser risk of fire hazards. Besides, they do not contain harmful substances such as mercury.

- Customized Lighting Solutions

LED lights are available in different designs, for example, high bays, floodlights, and panel lights, according to specific factory needs.

Implementing LED Factory Lighting

For the installation of LED factory lighting, consider the following process:

- Lighting Audit: Assess the present conditions and identify areas for improvement.

- Selection of Fixtures: The lux level, CRI, and beam angle are to be considered to finalize LED lights.

- Installation of Smart Controls: This process will include motion sensors and dimmers to optimize the use of energy.

- Installation Following Standards: It will comply with local and international standards of lighting.

Advantages of LED Factory Lighting

LED lighting has changed the entire industrial scenario by providing far better performance and efficiency than any other type of lighting. Here's why LEDs are the preferred choice:

- Energy Efficiency: LEDs consume much lesser energy and reduce electricity bills.

- Long Lifespan: LEDs have a lifespan of 50,000+ hours that reduce the maintenance costs.

- Improved Brightness: LEDs provide good quality illumination to meet lighting standards.

- Durability: LEDs are made to stand up to harsh industrial conditions and are resistant to shock and vibrations.

Selecting the Appropriate LED High Bay Lights for Your Factory

Design: These are small, round lights that can be mounted at high ceilings, often between 15 and 50 feet.

Applications: Suitable for large open areas, such as warehouses and production rooms.

Advantages: High lumen output, good heat dissipation, and easy installation.

- Design: These are rectangular-shaped fixtures with wide light distribution, which makes them suitable for wide areas.

- Applications: It is used in assembly lines, storage areas and factories with low ceilings.

- Benefits: Uniform lighting, neat design and energy efficiency.

Conclusion

Adherence to lighting standards is essential to ensure safety and efficiency in factory settings. LED factory lighting not only meets these standards but provides further benefits like energy savings and low maintenance. Upgrading to LED solutions can thus help create a safer and more productive workplace while reducing operational costs for factories.

If you are looking at upgrading your lighting in your factory, check out our latest advanced LED lighting solutions specifically designed for industrial purposes. Reach out to us today