In the world of logistics and storage, warehouses play a pivotal role in ensuring the smooth flow of goods and materials. To maintain efficiency and safety within these vast spaces, proper lighting is of utmost importance. In this article, we will delve into the intricacies of warehouse lighting, with a specific focus on high bay LED lights, exploring the recommended practices and the benefits they bring to the table.

Table of Contents

- Introduction

- Importance of Warehouse Lighting

-

Types of Warehouse Lighting

- High-Intensity Discharge (HID) Lighting

- LED Lighting

- Fluorescent Lighting

-

Considerations for Warehouse Lighting

- Illuminance Levels

- Uniformity

- Color Temperature

- Energy Efficiency

- Benefits of Adequate Warehouse Lighting

- High Bay LED Lights: The Ideal Solution

-

Common Warehouse Lighting Problems

- Flickering Lights

- Glare

- Inadequate Illuminance

- Best Practices for Warehouse Lighting

- Case Studies

- Conclusion

- Frequently Asked Questions (FAQs)

1. Introduction

Warehouse lighting is a critical aspect of warehouse management that is often overlooked. It goes beyond simply illuminating a space; it impacts safety, productivity, and overall operational costs. In this article, we will explore the importance of warehouse lighting, the various types available, and the considerations that need to be taken into account when selecting the right lighting solution.

2. Importance of Warehouse Lighting

Proper lighting in a warehouse is not just about creating a well-lit environment; it goes hand in hand with safety and efficiency. Here are some reasons why warehouse lighting is crucial:

- Improved Safety: Adequate lighting reduces the risk of accidents and injuries, allowing workers to navigate the space safely.

- Enhanced Productivity: Well-lit warehouses promote better visibility, helping employees work more efficiently.

- Accurate Inventory Management: Proper lighting ensures that inventory is accurately tracked and managed.

- Energy Efficiency: Choosing the right lighting technology can lead to significant energy savings.

3. Types of Warehouse Lighting

Warehouses can be lit using various lighting technologies, each with its own set of advantages and disadvantages.

High-Intensity Discharge (HID) Lighting

HID lighting, including metal halide and high-pressure sodium lamps, has been a traditional choice for warehouse lighting. It offers bright illumination but may consume more energy compared to newer technologies.

LED Lighting

LED lighting, especially high bay LED lights, has gained popularity for its energy efficiency and long lifespan. LEDs provide consistent and bright lighting while reducing operational costs.

Fluorescent Lighting

Fluorescent lighting is known for its affordability and decent energy efficiency. However, it may not offer the same brightness as LED lighting.

4. Considerations for Warehouse Lighting

When selecting warehouse lighting, several factors need to be considered to ensure optimal performance.

Illuminance Levels

The required level of brightness varies depending on the warehouse's activities. Adequate illuminance levels are crucial for safety and productivity.

Uniformity

Uniform lighting distribution is essential to eliminate dark spots and shadows, creating a well-lit and safe environment.

Color Temperature

The color temperature of lighting affects visibility and employee comfort. Choosing the right color temperature is vital for a productive workspace.

Energy Efficiency

Selecting energy-efficient lighting options can significantly reduce operational costs and environmental impact.

5. Benefits of Adequate Warehouse Lighting

Choosing the right warehouse lighting can bring about several benefits:

- Reduced Accidents: Adequate lighting minimizes the chances of accidents and injuries.

- Increased Productivity: Well-lit spaces promote higher productivity and efficiency among workers.

- Better Inventory Management: Accurate inventory tracking becomes easier with proper lighting.

- Cost Savings: Energy-efficient lighting solutions like high bay LED lights can lead to substantial cost savings over time.

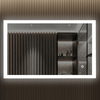

6. High Bay LED Lights: The Ideal Solution

High bay LED lights are specifically designed for warehouse environments. They are suspended at higher mounting heights, providing uniform and efficient lighting for large, open spaces. Here's why they are the ideal solution:

- Energy Efficiency: High bay LED lights are highly energy-efficient, reducing electricity consumption and operational costs.

- Longevity: LED technology ensures a longer lifespan, reducing the need for frequent replacements.

- Brightness and Uniformity: High bay LEDs offer exceptional brightness and uniform lighting, enhancing safety and productivity.

7. Common Warehouse Lighting Problems

Despite the importance of warehouse lighting, several common issues can arise:

Flickering Lights

Flickering lights can be distracting and pose safety risks. Identifying and addressing these issues promptly is essential.

Glare

Excessive glare can reduce visibility and lead to eye strain. Proper lighting design can help mitigate glare problems.

Inadequate Illuminance

In some cases, lighting may not meet the required illuminance levels, impacting productivity and safety.

8. Best Practices for Warehouse Lighting

To optimize warehouse lighting, consider the following best practices:

- Conduct a lighting audit to assess current lighting conditions.

- Choose high bay LED lights or other suitable lighting technology based on your specific needs.

- Implement lighting controls to adjust brightness as needed.

- Regularly maintain and replace lighting fixtures to ensure optimal performance.

9. Case Studies

Explore real-world examples of warehouses that have successfully implemented high bay LED lighting solutions to improve safety and efficiency.

10. Conclusion

Warehouse lighting is more than just illuminating a space; it directly impacts safety, productivity, and operational costs. Choosing the right lighting technology, such as high bay LED lights, and considering illuminance levels, uniformity, color temperature, and energy efficiency can lead to significant improvements in all these areas.

11. Frequently Asked Questions (FAQs)

Q1: What are the recommended illuminance levels for warehouse lighting?

A1: The recommended illuminance levels for warehouse lighting can vary depending on the specific tasks performed in the space. Generally, for general storage areas, a minimum of 20-30 foot-candles (fc) is recommended, while areas with more detailed tasks may require 50-75 fc or even higher. It's essential to conduct a lighting audit to determine the precise illuminance levels needed for your warehouse's activities.

Q2: Can high bay LED lights reduce energy costs in a warehouse?

A2: Yes, high bay LED lights are known for their energy efficiency. They can significantly reduce energy costs in a warehouse when compared to traditional lighting technologies like HID or fluorescent lighting. LED lights consume less electricity, generate less heat, and have a longer lifespan, resulting in substantial energy savings and reduced operational expenses.

Q3: How can I address glare issues in my warehouse with high bay LED lighting?

A3: To address glare issues in your warehouse with high bay LED lighting, consider the following measures:

- Opt for LED fixtures with diffusers or lenses to reduce direct glare.

- Properly position fixtures to avoid direct light shining into employees' eyes.

- Implement lighting controls to adjust brightness levels when needed, reducing glare during specific tasks.

- Conduct a lighting audit and consult with lighting experts to design a layout that minimizes glare while ensuring adequate illumination.

Q4: What is the typical lifespan of high bay LED warehouse lighting fixtures?

A4: High bay LED lighting fixtures are known for their longevity. On average, high-quality LED fixtures can last anywhere from 50,000 to 100,000 hours or more. This extended lifespan not only reduces maintenance and replacement costs but also contributes to sustainability efforts by reducing waste.

Q5: Are there government incentives for switching to energy-efficient lighting solutions like high bay LEDs?

A5: Yes, in many regions, there are government incentives and rebates available for businesses that switch to energy-efficient lighting solutions like high bay LEDs. These incentives aim to encourage the adoption of environmentally friendly technologies and reduce energy consumption. To take advantage of these incentives, businesses should check with their local utility companies or government agencies for available programs and eligibility criteria.