Filter and sort

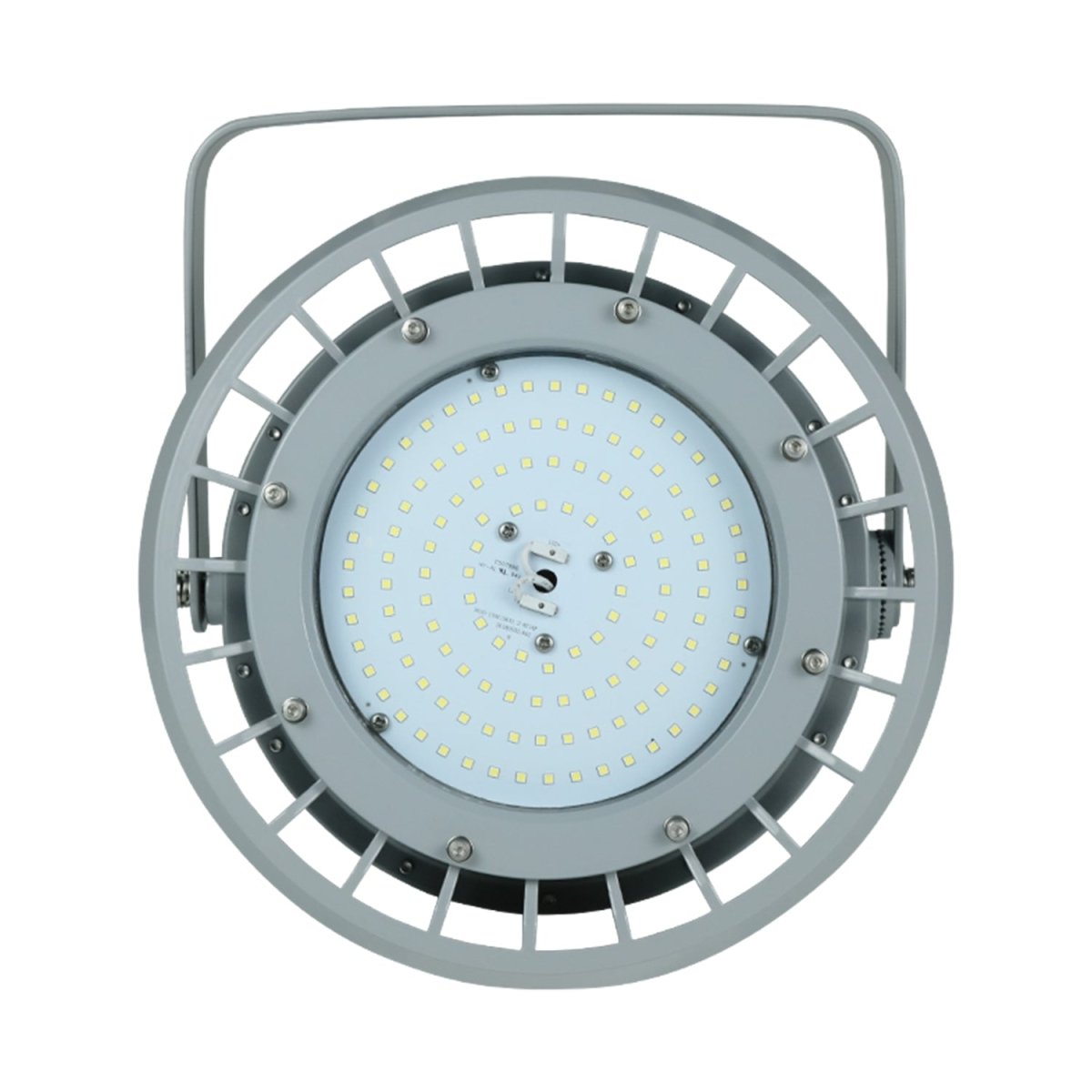

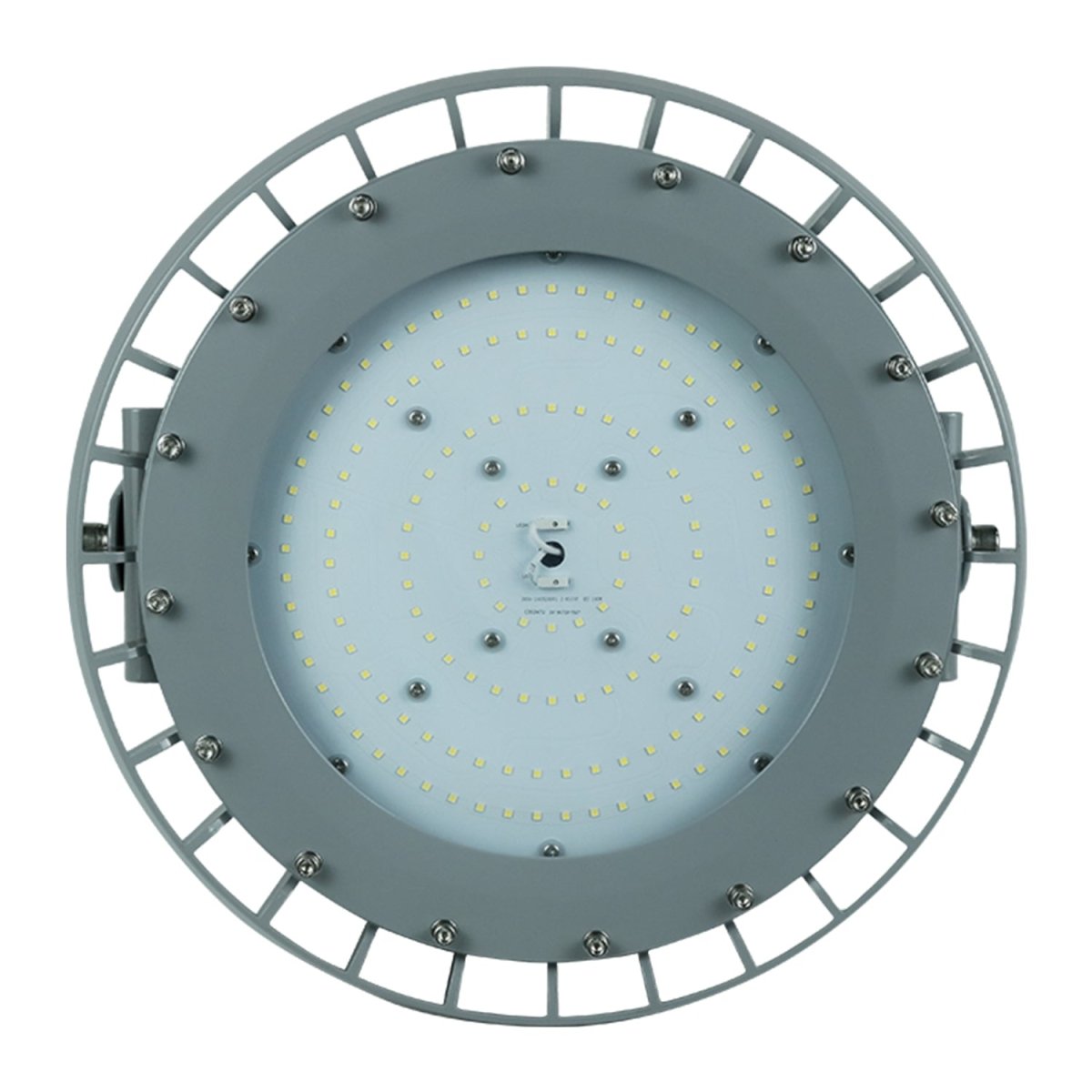

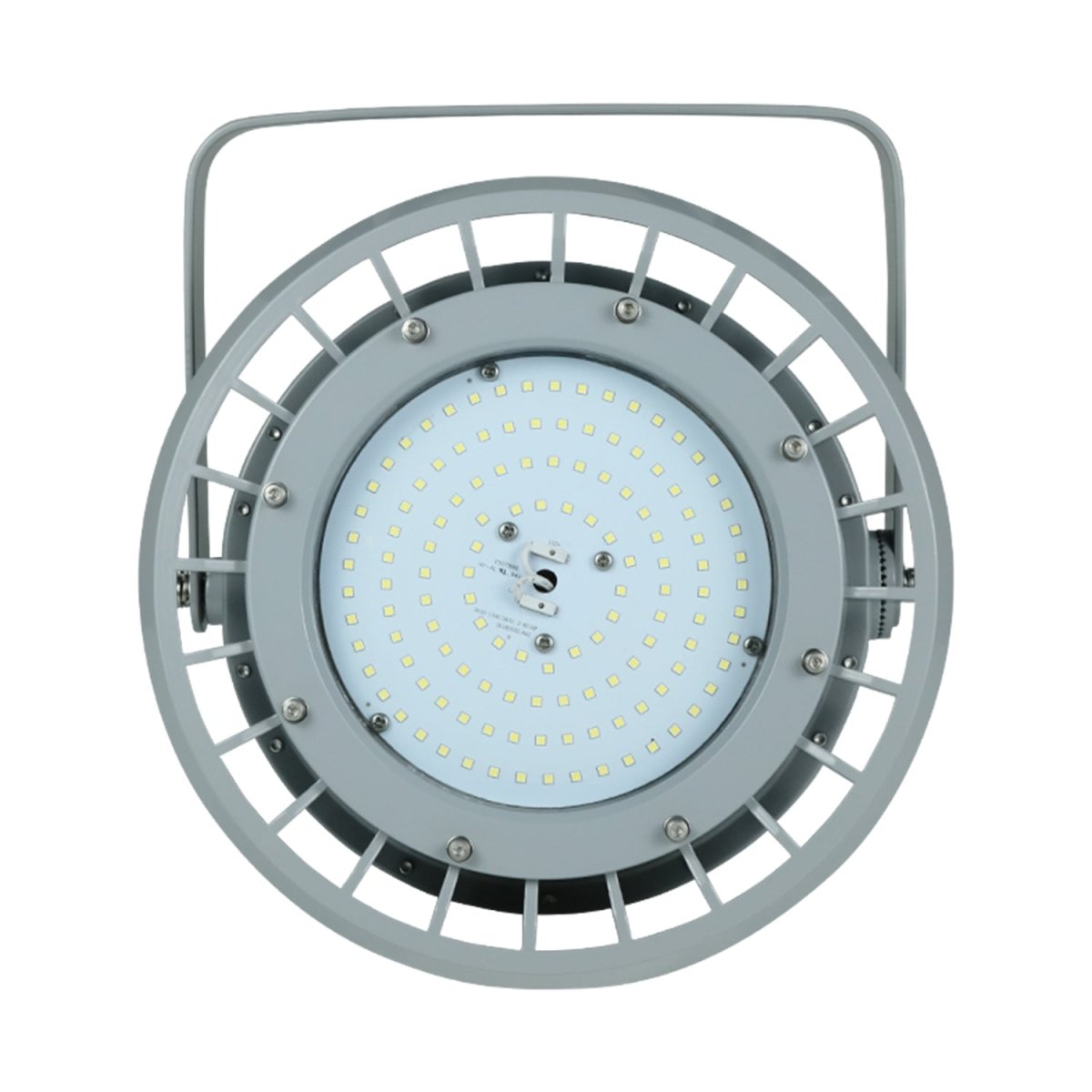

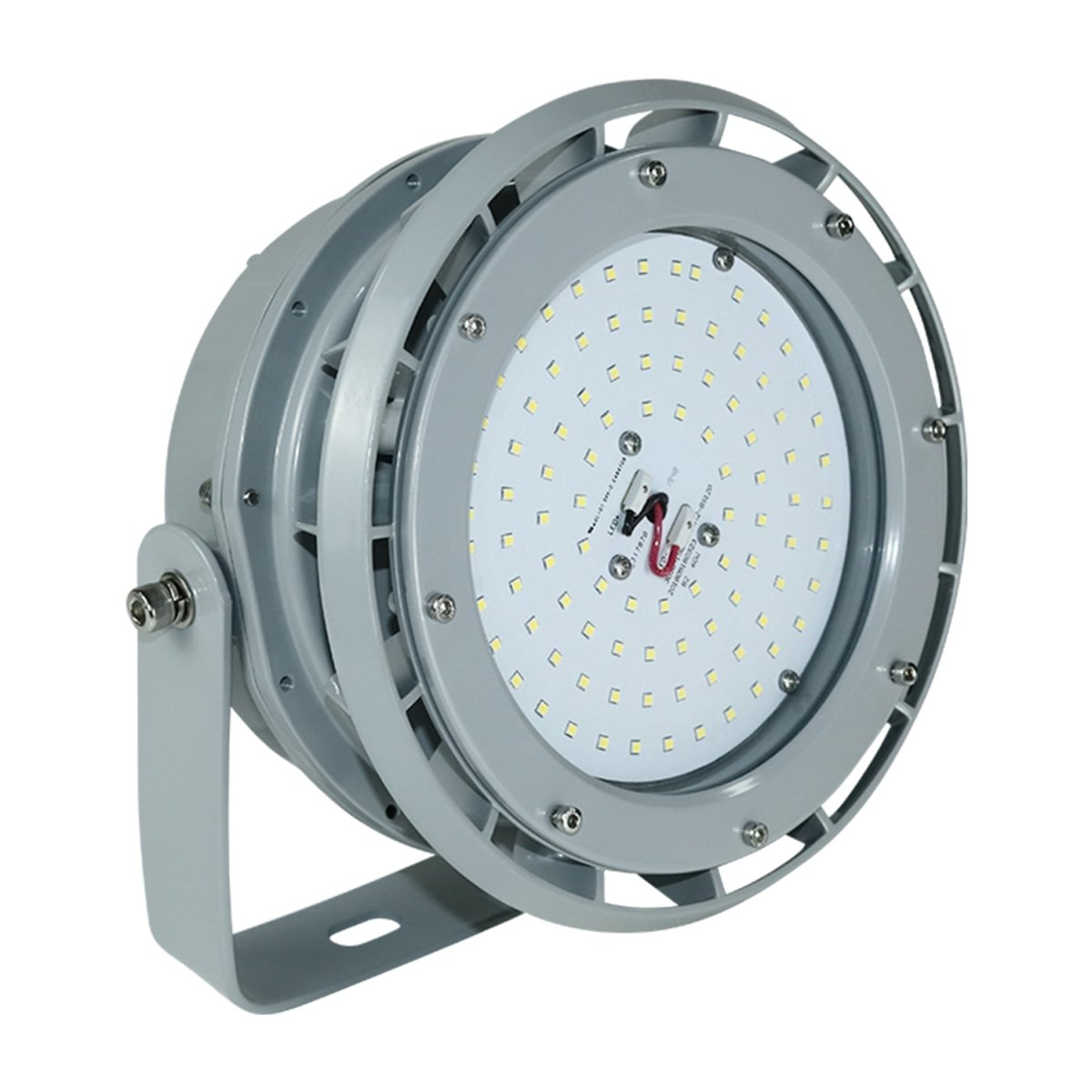

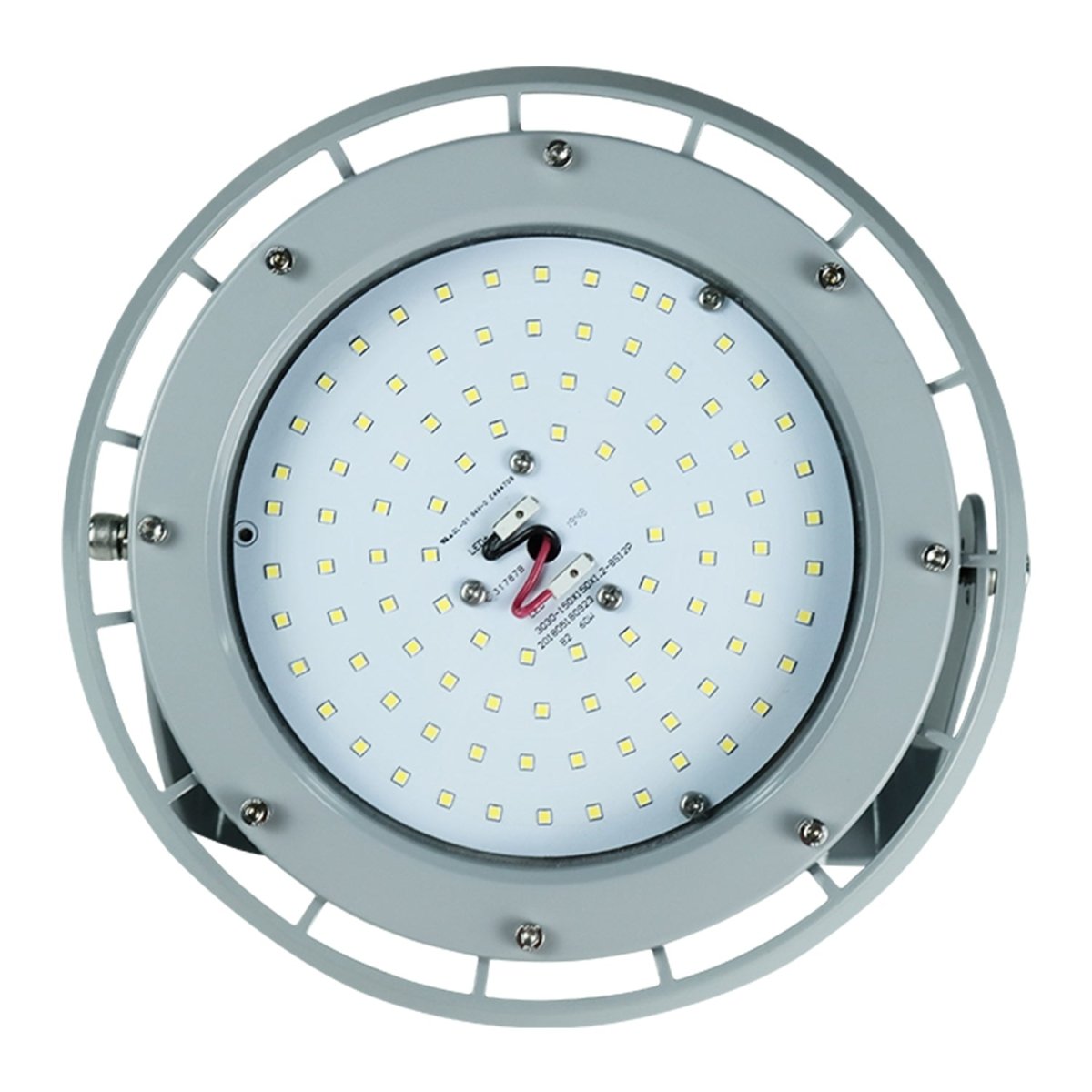

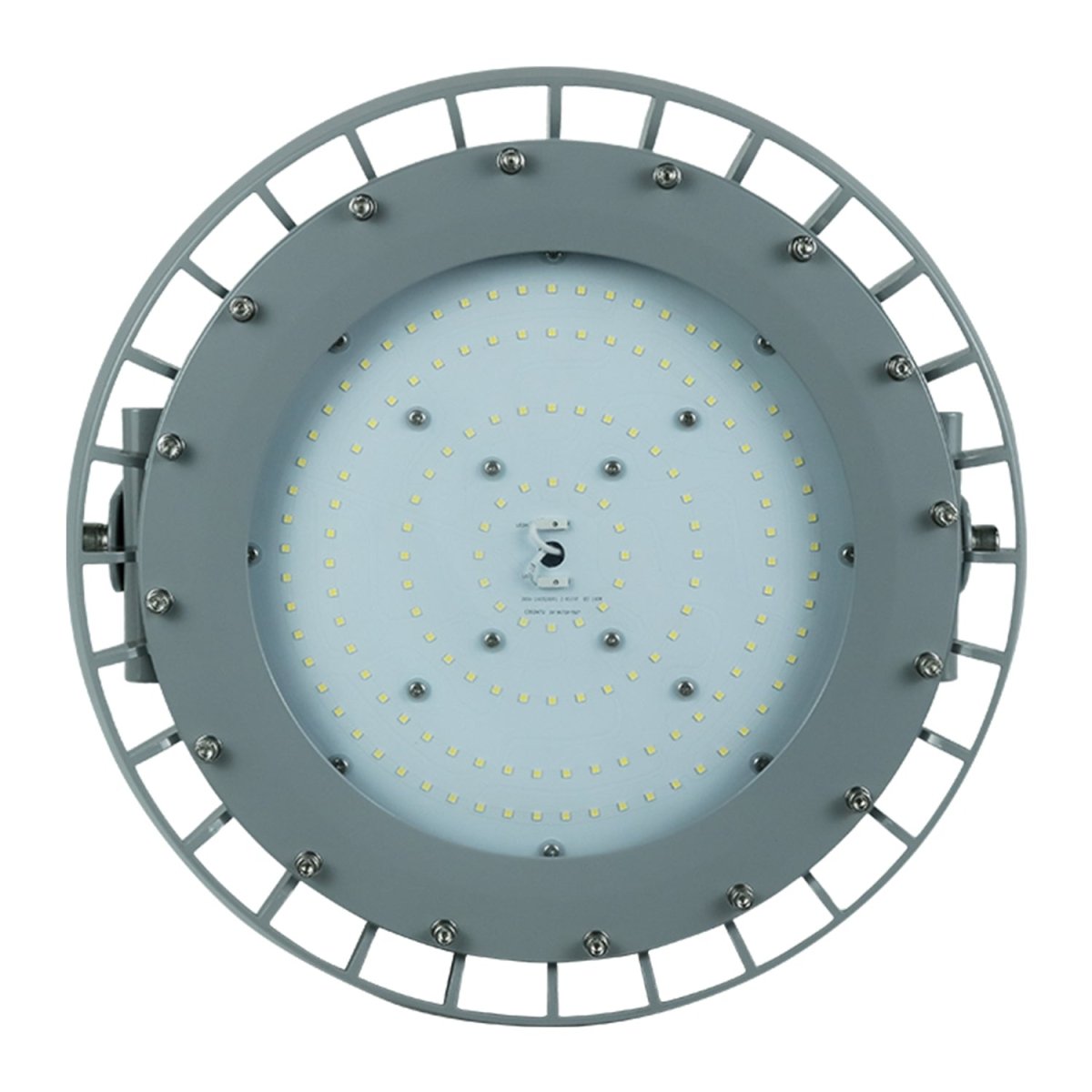

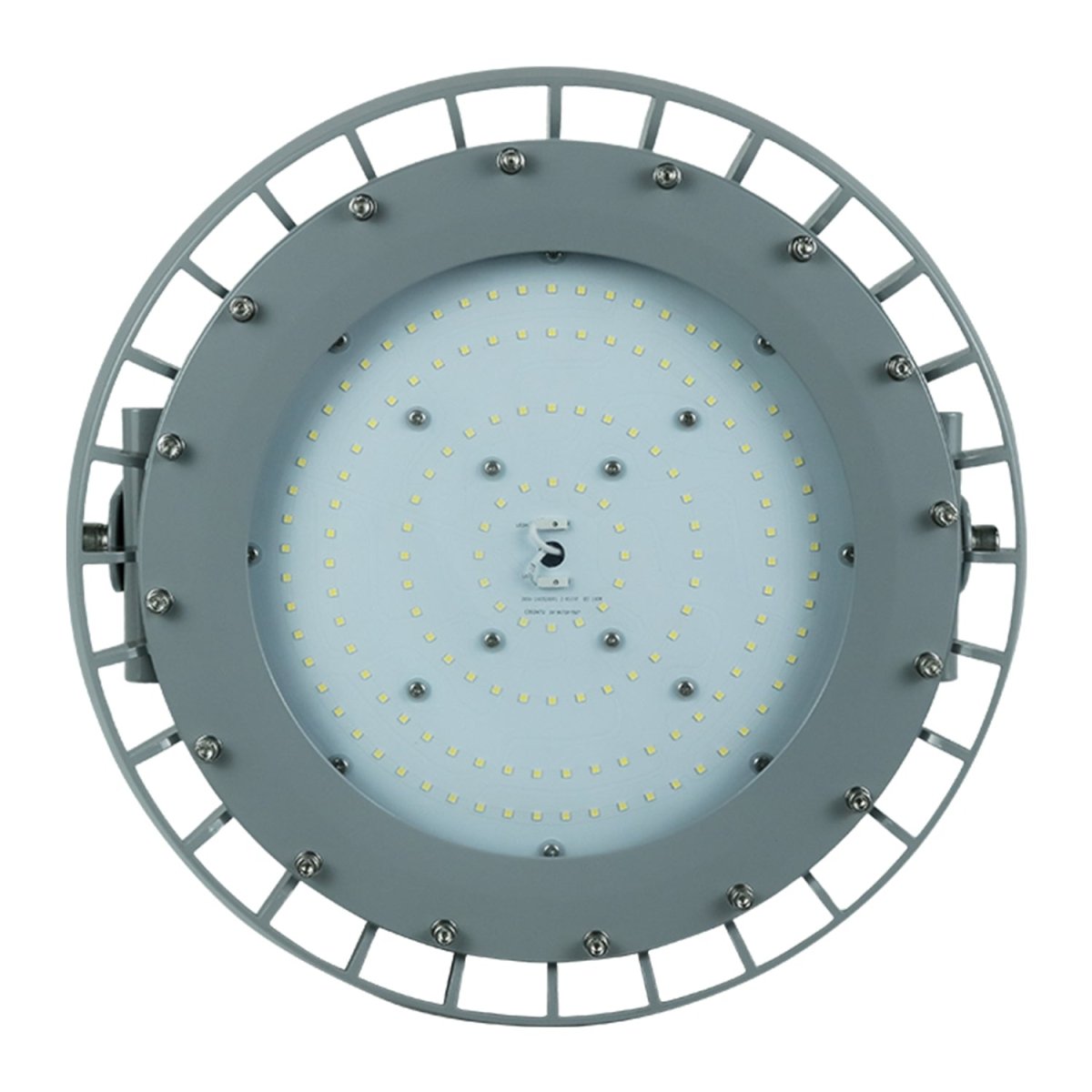

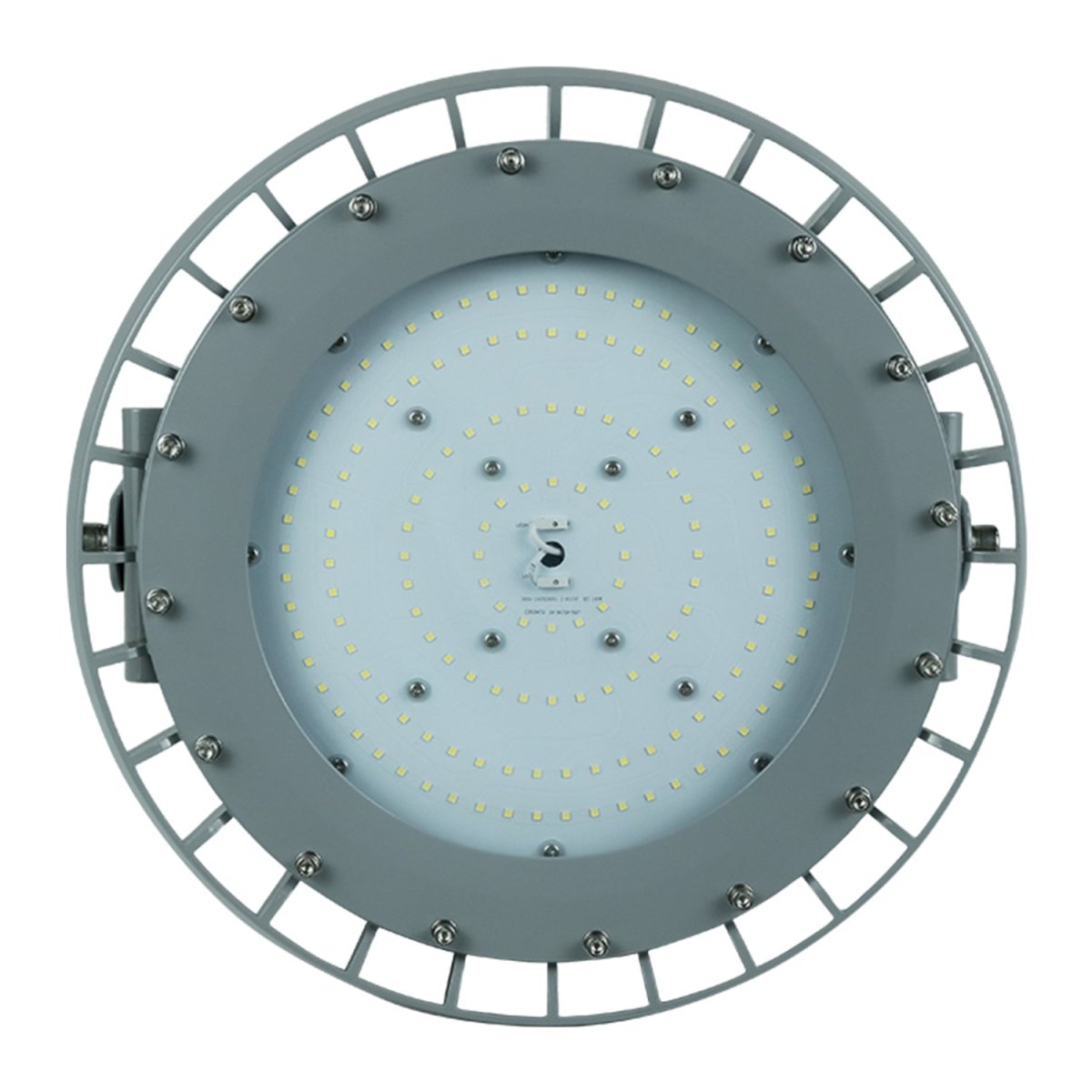

LED Explosion Proof Lighting For Hazardous Areas

The Explosion Proof LED lighting for Hazardous Areas is the perfect solution that will not The housing of these explosion proof lighting fixtures is made up of premium-quality material that will not stay maintained in locations with high atmospheric pressure. Furthermore, these lights have a wide beam angle illumination that evenly disperses in the premises. Find suitable explosion proof LED lights for extremely dusty and damp locations.

-

FREE SHIPPING on orders over $99

- MPN: 60WB2D50D120-50K

- Warranty: 5 Years

Brightness: 8400 LumensWattage: 60 WattCCT: 5000 Kelvin$428.99 $506.99Save $78.00 (16%)FREE SHIPPING on orders over $99- MPN: 150WB3D50D120-50K

- Warranty: 5 Years

Brightness: 20250 LumensWattage: 150 WattCCT: 5000 Kelvin$766.99 $844.99Save $78.00 (10%)FREE SHIPPING on orders over $99- MPN: 200WB3D50D120-50K

- Warranty: 5 Years

Brightness: 27000 LumensWattage: 200 WattCCT: 5000 Kelvin$766.99 $909.99Save $143.00 (16%)FREE SHIPPING on orders over $99- MPN: 300WB4D50D120-50K

- Warranty: 5 Years

Brightness: 42000 LumensWattage: 300 WattCCT: 5000 Kelvin$974.99 $1,202.99Save $228.00 (19%)FREE SHIPPING on orders over $99- MPN: 400WB4D50D120-50K

- Warranty: 5 Years

Brightness: 56000 LumensWattage: 400 WattCCT: 5000 Kelvin$1,104.99 $1,299.99Save $195.00 (16%)FREE SHIPPING on orders over $99- MPN: 60WBN50D120-50K

- Warranty: 5 Years

Brightness: 8400 LumensWattage: 60 WattCCT: 5000 Kelvin$584.99 $682.99Save $98.00 (15%)FREE SHIPPING on orders over $99- MPN: 100WB3N50D120-50K

- Warranty: 5 Years

Brightness: 13500 LumensWattage: 100 WattCCT: 5000 Kelvin$610.99 $779.99Save $169.00 (22%)FREE SHIPPING on orders over $99- MPN: 80WAD50D120-50K

- Warranty: 5 Years

Brightness: 10800 LumensWattage: 80 WattCCT: 5000 Kelvin$597.99 $714.99Save $117.00 (17%)FREE SHIPPING on orders over $99- MPN: 100WAD50D120-50K

- Warranty: 5 Years

Brightness: 13500 LumensWattage: 100 WattCCT: 5000 kelvin$649.99 $779.99Save $130.00 (17%)FREE SHIPPING on orders over $99- MPN: 200WA3D50D120-50K

- Warranty: 5 Years

Brightness: 27000 LumensWattage: 200 WattCCT: 5000 Kelvin$766.99 $909.99Save $143.00 (16%)FREE SHIPPING on orders over $99- MPN: 250WA4D50D120-50K

- Warranty: 5 Years

Brightness: 35000 LumensWattage: 250 WattCCT: 5000 Kelvin$935.99 $1,137.99Save $202.00 (18%)FREE SHIPPING on orders over $99- MPN: 400WA4D50D120-50K

- Warranty: 5 Years

Brightness: 56000 LumensWattage: 400 WattCCT: 5000 Kelvin$1,104.99 $1,299.99Save $195.00 (16%)FREE SHIPPING on orders over $99- MPN: 60WA2D50D120-50K

- Warranty: 5 Years

Brightness: 8400 LumensWattage: 60 WattCCT: 5000K$503.99 $584.99Save $81.00 (14%)FREE SHIPPING on orders over $99- MPN: 150WA3D50D120-50K 200-480V

- Warranty: 5 Years

Wattage: 150 WattCCT: 5000 kelvin$714.99 $942.99Save $228.00 (25%)FREE SHIPPING on orders over $99- MPN: 150WA3N50D120-50K

- Warranty: 5 Years

Brightness: 20250 LumensWattage: 150 WattCCT: 5000 Kelvin$844.99 $1,723.99Save $879.00 (51%)FREE SHIPPING on orders over $99- MPN: 60WAN50D120-50K

$571.99 $682.99Save $111.00 (17%)About LED Explosion Proof Lighting For Hazardous Areas

When safety and efficiency are paramount, LED Explosion Proof Lighting emerges as the ultimate solution for hazardous areas. Designed to provide reliable illumination in environments prone to explosive gases, vapors, or combustible dust, these fixtures ensure both performance and protection.

Why Choose LED Explosion Proof Lighting?

-

Safety First: Engineered to prevent ignition in potentially explosive atmospheres, these lights meet stringent safety standards, reducing risks in hazardous locations like oil rigs, chemical plants, or grain storage facilities.

-

Energy Efficiency: LED technology consumes less power while delivering high-quality light, significantly lowering energy costs without compromising brightness.

-

Durability: Built to withstand harsh conditions, explosion-proof LED fixtures are resistant to corrosion, extreme temperatures, and vibrations, making them perfect for tough environments.

-

Low Maintenance: With a long lifespan and minimal maintenance needs, LED explosion-proof lights are an economical choice for industrial settings.

Applications of LED Explosion Proof Lighting

Ideal for use in Class I, II, and III hazardous areas, these fixtures cater to diverse industries, including:

-

Oil & Gas: Offshore rigs, refineries, and drilling operations.

-

Chemical Processing Plants: Environments with volatile substances.

-

Mining Operations: Zones prone to explosive dust or gases.

-

Grain & Food Storage Facilities: Areas with combustible particulate matter.

-

Pharmaceutical Manufacturing: Sensitive environments requiring clean, safe lighting.

Features of Our LED Explosion Proof Lighting

-

Advanced Protection: Certified for hazardous locations with cutting-edge design to prevent accidental ignition.

-

Superior Brightness: High-lumen output for clear visibility, ensuring safety and productivity.

-

Variety of Options: Available in multiple wattages, beam angles, and mounting styles to meet specific application needs.

-

Environment-Friendly: Mercury-free and recyclable materials align with sustainability goals.

Why Buy From LEDMyplace?

At LEDMyplace, we offer premium-quality LED Explosion Proof Lighting tailored to meet industry standards. With competitive pricing, bulk discounts, and dedicated customer support, we ensure you find the perfect lighting solution for hazardous environments.

Invest in safety, energy efficiency, and durability with LED Explosion Proof Lighting from LEDMyplace. Browse our collection today and illuminate your hazardous areas with confidence!

Frequently Asked Questions

Q: Where is explosion-proof lighting typically used?

A: Explosion-proof lighting is commonly used in industries and environments where there is a risk of flammable or explosive substances being present. This includes oil and gas refineries, chemical plants, petrochemical facilities, mining operations, paint booths, grain elevators, and other hazardous locations.Q: How does explosion-proof lighting differ from regular lighting fixtures?

A: Explosion-proof lighting fixtures are constructed with robust materials and specialized designs to contain any potential sparks or heat generated by the light source. They are also sealed to prevent the entry of flammable substances, making them safe to use in volatile environments where standard lighting fixtures would be dangerous.Q: Are there different classifications of explosion-proof lighting?

A: Yes, explosion-proof lighting fixtures are classified based on the specific hazardous environment they are intended for. Common classifications include Class I for flammable gases and vapors, Class II for combustible dust, and Class III for fibers and flyings.Q: What types of light sources are used in explosion-proof lighting fixtures?

A: Explosion-proof lighting fixtures can use various light sources, including incandescent bulbs, fluorescent tubes, high-intensity discharge (HID) lamps, and LED (light-emitting diode) technology. LED explosion-proof lights are becoming increasingly popular due to their energy efficiency, long lifespan, and durability.Q: How are explosion-proof lighting fixtures tested for safety?

A: Explosion-proof lighting fixtures undergo rigorous testing and certification by recognized safety organizations, such as Underwriters Laboratories (UL) or the International Electrotechnical Commission (IEC). These tests evaluate the fixtures' ability to contain sparks, flames, and heat, ensuring they meet the necessary safety standards for hazardous environments.Q: Can explosion-proof lighting fixtures be used in wet or outdoor environments?

A: Yes, some explosion-proof lighting fixtures are rated for use in wet or outdoor environments. These fixtures are designed to withstand exposure to water and other elements while maintaining their explosion-proof properties.Q: Can explosion-proof lighting fixtures be used in areas with dust or fibers that could be combustible?

A: Yes, explosion-proof lighting fixtures designed for Class II and Class III hazardous locations are suitable for use in areas with combustible dust or fibers. These fixtures are engineered to prevent the ignition of such materials and maintain safety in those environments.- Choosing a selection results in a full page refresh.